cnc machine smashes hole in wall Holes are spotted and then drilled in 6061-T6 with a Norseman HSS Jobber 0.25" 135deg. I've tried 4 different brands of drills and get the same issue. 0.25" dia., 0.5" deep hole, the first 0.175" depth gives a spiralled finish . They are commonly called "barn stars" since they are often seen gracing the fronts of barns. We did some research and here is what we found. In most cases today, homeowners hang the decorative old-looking metal stars on their .

0 · Your Guide to Thin Wall Milling

1 · Top 10 CNC Machining Defects And How To Fix

2 · CNC Machining Defects and Failures: Causes

3 · CNC Machining

4 · 8 Typical CNC Milling Parts’ Defects, Causes, and

5 · 7 Common Issues in Setup and Maintenance of CNC

6 · 5 Common CNC Machining Problems, Errors and Solutions

7 · 3 Most Common CNC Machining Defects & How to Troubleshoot

8 · 16 Tips to Avoid Tearout and Splintering [ CNC Machining Plywood ]

Exploring the Tapestry of Solar Panel Junction Box Types In the symphony of solar panel technology, junction boxes take on the role of orchestrators, ensuring the harmony of electricity flow within the panels. As .

Holes are spotted and then drilled in 6061-T6 with a Norseman HSS Jobber 0.25" 135deg. I've tried 4 different brands of drills and get the same issue. 0.25" dia., 0.5" deep hole, the first 0.175" depth gives a spiralled finish . Hey guys, #31 drill, 1.365" deep, at 3183 rpm, .001" per flute feed (i have played with it from .0035" to .001"), pecking at .1" and mist coolant. About every five holes the drill breaks .

Understanding common CNC machining defects and their causes is paramount for efficient machining operations and quality assurance. This guide explores prevalent CNC machining . Here's a look at some of the commonly encountered issues in the setup and maintenance of CNC machines with potential remedies to correct them. Computer Numerical Control (CNC) machines are automated or computer . Mismatched seams or joints in CNC machining occur when two parts or sections of a machined component do not align correctly, leading to uneven or misaligned surfaces. Cause: Inaccurate programming or tool path . A CNC machine vibrates due to various reasons, such as worn machine spindle bearings, improper cutting parameters, and unbalanced tool holders, leading to reduced accuracy, tool life, and rigid machined surface finish.

Your Guide to Thin Wall Milling

The main causes are worn cutting tools, machine vibrations, incorrect tool alignment, or improper cutting parameters. To prevent taper, it’s essential to use sharp cutting tools, proper tool holders, and parts-clamped . Milling part features with thin wall characteristics, while also maintaining dimensional accuracy and straightness, can be difficult at best. Although multiple factors contribute, some . Depending on your bit type, you may splinter badly when the bit blasts out the bottom of the hole. Fixing this problem can boil down to: Use a different bit, such as a Brad .

steel city metal handy extension box

I agree with the guy in the video and think that the counterweight broke it's bolts first, flew out through the enclosure and put the holes in the wall we're seeing. The resulting imbalance broke the pull stud and then the holder and flycutter . The hole then tapers at 1° per side for 0.724" until the ID becomes 0.234". The final portion of the hole tapers at 3° per side for a distance 0.276" down to the final ID of 0.205". Overall, the hole is 1.925" long, 0.926" of it being straight, and 1" of it as two different tapers. The OD in the beginning is 0.375", leaving 0.058" of wall . We are drilling, and then circle milling a .687" hole thru one wall right on the centerline of the tubing. We are circle milling only to keep the burr to a minimun for hand deburring. We are looking for a tool or process to deburr the hole in . My problem right now is I am trying to find a way to drill holes in tubing (through the tube). I was told since the bit will flex it will not drill accurately through the tube. Now at most we are going to have 6 holes in different places (for bolts to fasten through). We are drilling mostly square tubing (2" x 2") at .065" wall thickness.

Top 10 CNC Machining Defects And How To Fix

Machine has run parts before and previous drill was the exact same and ran 150 holes. It started to oversize by .002" so drill was changed. Now oversizing by .005 Parameters - 4140 steel, .159" drill, .300" deep, .200" peck, 1500rpm, 7ipm, coolant 10%, ER 32 holder but collet has to clamp.Also, rough and finish. Rough the holes leaving a little bit for cleanup (0.1 mm or so) and then cut again to finished size. Interpolating a 3mm hole with a 2mm endmill is a very small linear path, so if your feedrate is decently high you will end up with smaller holes due to the machine being unable to keep up, so to speak. Is there a way to cut countersunk holes in VCarve so that screws that require them can be used without drilling the countersinks by hand after the CNC job is done? In the case of the sink depth it would be either zero or whatever else is required ( but zero is needed). It's important to get the screw wall angle correct.

As the disk approaches the edge of the bore's intersection, it falls off the bore wall and allows the cutter, which is under load from the deflected flexible coupling, to machine the burr. Like a cam follower, the disk traces the contour of the cross-hole intersection so only the burred areas come in contact with the cutter.We offer a range of CNC machines, including CNC grinding machines, CNC hobbing machines, CNC milling machines, CNC drilling and tapping machines, and vertical and horizontal machining centers. We use advanced technology and materials .

+1 on split point drills, they’re also great for hand use. I don’t know when I wouldn’t use a split point drill honestly, except maybe if I need a prick-punched hole to be super accurate for some reason. McMaster sells screw machine length drill bits (basically short drill bits) with split points for -3 each. Mcgyver's point about the 'hammering' action could be valid. I think it would depend a lot on the machine size versus the rota-broach size; a machine spindle and chuck has a lot of mass so it is not going to feel the hammering from a small broach, not much anyway. Actually on a CNC machine I might be more concerned about the Z axis ball screw.

FULL KIT: M2 is a 3-Axis wall-mounted CNC cutting machine and comes with laser-cut, steel and powder coated mounting brackets, lead screw z-axis, built-in dust collection port, three ⅛‘’ router bits that offer extremely precise cuts. The router is not included. Compatible routers include: DeWalt611, Bosch Colt, Makita RT0700CX and EU .

I’ve spent considerable time researching System32 templates that are used with hand-held routers to drill shelf pin holes, assembly holes, and holes for System32 hardware. The two that are at the top of my list are the Festool LR32 system and the Schmitt32 system. Both are spendy, accurate, repeatable, and reliable. It doesn’t take too many ruined cabinet panels to .

On some CNC Vertical milling machines the spindle will go past the table edge OR the table goes past the spindle depending on how you look at it. On some of my Haas machine the spindle goes about an inch past the table. . That allows me to do some machine work, holes etc on the sides or ends of some plates. A. AARONT Stainless. Joined Feb 19 .

For larger diameter holes (D ≥30mm), a smaller drill (0.5-0.7 times the hole diameter) is initially used, followed by the corresponding reamer to improve machining quality and efficiency. Besides cylindrical holes, special . Fast hole drilling is 'fast' (think of a 1mm hole being drilled at 95mm/min in nickel alloy) but typically machines are made to only drill one hole at a time. When you can get 20+ electrodes on a die sinker, the benefits of a rotating electrode with 1000+psi flush pressure tend to . Drilling holes along a tube is a piece of cake with a CNC Mill :-) In the world of CNC machining, wall thickness should not be overlooked. Ensuring the correct thickness will result in a CNC machined part that meets specifications and has an excellent finish. However, if you’re grappling with a CNC part design and the wall thickness falls outside of our recommendations, chat with us. Our team will work with .

steel compartment storage boxes

Another prototype that was created in our workshop. Horizontal CNC milling machine which is ideal for drilling and milling holes in plates. ️V-Slot.pl#openb. When I had big batches involving thousands of holes a Tapmatic head comes into its own, goes in at X revs comes out a X 1.5 no spindle stops and reversals, very quick, and kind on the cnc machine As an alternative while the cnc is drilling and machining all the other features use a Tapmatic in a bench drill and just tap the drilled holes if it .

Then, when I cut out the center, I will do so with a ramping contour down to .007 above the table, and .005 from the final dimension on the wall. Then come in with a finish pass for the wall. The corners require a .120 radius so I will then come in with a 6mm end mill and a careful entry and re-machine those corners.

Drill or mill the hole to the correct depth and then use a small t-slot cutter to enlarge the hole below the existing threads. I did this recently and actually used a single point thread mill in place of the t-slot cutter, it worked great. As others have said, its easiest to ream dowel holes to get size. Helical milling can usally put the hole on location before reaming. Many holes can be finished nicely with helical milling, as long as you can hit the tolerance, and that depends a lot on the codition/quality of your machine, and the cutters you are using. I do have reamers (all carbide), but they are only used on repeat work where it's worth having that .0355", .0360", .0365" and .0370" reamer on hand since plastic never reams exactly the same hole size from batch to batch, and any hole right by a wall (making a thin wall) does weird shit too.

CNC Machining Defects and Failures: Causes

Made in the USA - Season 2 Episode 6: Why, and How, Hardinge is Reshoring Machine Tool Production In this episode of Made in the USA, several executives and senior staff at Hardinge give their first-person account of how they formulated the plan to shift the manufacturing of its milling and turning product lines from its Taiwan plant to its plant in Elmira, . Cnc not cutting correct size; Holes not coming out correct size . spindle bearings could be an additional factor.In the photograph of the project if you look really closely at the outer wall of the right hand recess there appear to be small steps in the surface and this is the classic sign of a spindle slightly out of square to the table.Do .

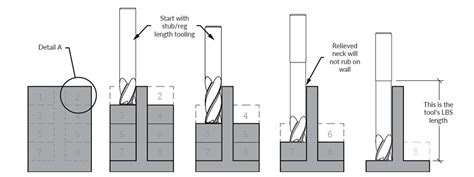

To support the walls during thin wall machining, keep a wide-cross section behind it. We recommend utilizing a “stepped down” approach, which divides the total wall height to manageable depths while working each side of the wall. The Axial Depth of Cut dimension will vary depending on the material (and its hardness) being cut.

steel city boxing hamilton north

steel city boxing gym newcastle

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

cnc machine smashes hole in wall|CNC Machining